One-sentence summary:

A breakthrough discovery that water vapor—not air expansion—causes bubble formation in PDMS-based PCR chips has led to a high-pressure liquid seal technique, greatly enhancing chip stability and diagnostic reliability.

Three brief takeaways:

- Root Cause Identified: Researchers found water vapor diffusion, not air expansion, drives bubble formation in PCR chips.

- Innovative Solution: A high-pressure liquid seal (≥109 kPa) eliminates bubbles and prevents sample evaporation without complex chip modifications.

- Wider Impact: This advancement improves PCR accuracy, simplifies chip design, and paves the way for more reliable, affordable diagnostics in healthcare.

A new discovery has reshaped our understanding of PCR chip technology: water vapor, not air expansion, is the primary culprit behind bubble formation in polydimethylsiloxane (PDMS)-based chips. This revelation has led to the development of a high-pressure liquid seal technique that effectively eliminates bubbles and prevents water loss during the polymerase chain reaction (PCR) process. The innovation simplifies chip design, enhances operational stability, and boosts the reliability of PDMS PCR chips, paving the way for more efficient applications in critical fields such as cancer screening and virus detection.

Cornerstone of Modern Diagnostics

Polymerase chain reaction (PCR) technology is a cornerstone of modern diagnostics, enabling precise nucleic acid quantification in applications ranging from disease detection to prenatal testing. Microfluidic chips, especially those made from PDMS, have gained traction due to their compact size, rapid reaction speeds, and ability to handle multiple reactions simultaneously. However, a persistent challenge has hindered their widespread adoption: the formation of bubbles and the loss of sample moisture during thermal cycling. These issues not only alter sample volumes but also increase the risk of cross-contamination and fluctuations in ion concentration, ultimately compromising PCR accuracy. Addressing these technical roadblocks has become a pressing research priority in the quest for more reliable PCR chip technology.

Improving PCR Chip Performance

Published in September 2024, in Microsystems & Nanoengineering, researchers from the Shanghai Institute of Microsystem and Information Technology, Chinese Academy of Sciences, unveiled a novel high-pressure liquid seal technique that effectively counters bubble formation in PDMS-based PCR chips. Their study conclusively demonstrated that water vapor diffusion, rather than air expansion, is the driving force behind bubble formation. By creating a high-pressure liquid environment, the researchers successfully prevented vapor-induced bubbles, significantly improving PCR chip performance and reliability.

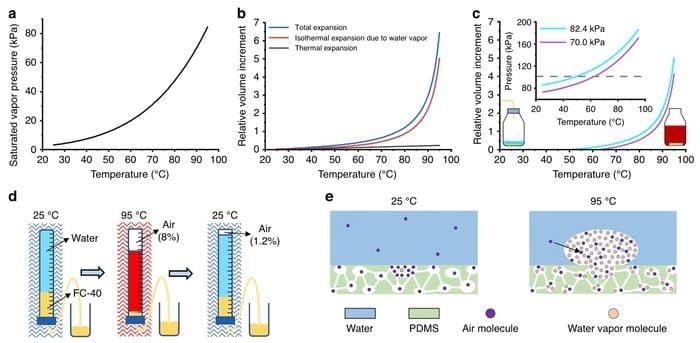

The research team discovered that at elevated temperatures, water vapor saturation pressure rises sharply, leading to bubble formation within PDMS chips. Unlike previous assumptions that attributed bubbles to trapped air expansion, experiments confirmed that water vapor can penetrate PDMS and create bubbles even in the absence of significant thermal expansion. To counter this, the scientists developed a high-pressure liquid seal technique, maintaining an internal pressure above 109 kPa. This approach not only prevents bubble formation but also curbs water loss, eliminating the need for complex structural modifications or additional sealing materials. Furthermore, the liquid seal acts as a protective barrier, isolating the chip from external air and mitigating the “respiratory” effect that accelerates evaporation. The technique was successfully validated in digital PCR (dPCR) chips, demonstrating its potential to maintain sample integrity and minimize cross-contamination.

“This study marks a significant leap forward in PCR chip technology by resolving the long-standing issue of bubble formation,” says Dr. Tiegang Xu, one of the lead researchers. “The high-pressure liquid seal technique simplifies chip design while significantly enhancing PCR reliability and efficiency, making it more accessible for a wide range of diagnostic applications.”

The implications of this breakthrough extend far beyond laboratory settings. By ensuring accurate and consistent PCR results, the high-pressure liquid seal technique holds promise for revolutionizing medical diagnostics, particularly in cancer screening, infectious disease detection, and prenatal testing. The ability to prevent bubble formation and water loss enhances chip durability, reducing the likelihood of errors and contamination. Moreover, this innovation could drive the development of cost-effective, disposable PCR chips, making cutting-edge diagnostic tools more accessible in resource-limited regions. With its simplicity and effectiveness, the technique is poised to accelerate the integration of microfluidic PCR technology into both clinical practice and research, unlocking new possibilities in precision medicine.

Featured Image: The impact of water vapor on bubble formation during PCR (temperature: 25–95 °C, pressure: 101.325 kPa). a Saturation vapor pressure of water. b Thermal expansion only causes a slight increase in gas volume (black line), while the equilibrium effect of water vapor leads to a larger volume of isothermal expansion (red line). The synergistic effect of thermal expansion and isothermal expansion of water vapor results in the maximum increase in bubble volume (blue line). c Calculated bubble volume generated from degassed porous PDMS during PCR. The inset shows the total pressure of air and water vapor if the volume is constant. d The volume of saturated water vapor formed by the air dissolved from the water. Rapid cooling reduced the volume from 8% to 1.2%, indicating that the main component of these bubbles at 95 °C is water vapor. e Possible mechanisms for bubble formation involving the equilibrium of water vapor and the overflow of air in the PDMS and PCR solutions. Image: Microsystems & Nanoengineering