Summary:

Festo’s SupraMotion uses superconducting technology to enable fully automated, contactless handling of materials across sterile and non-sterile environments in pharmaceutical and medical labs.

Takeaways:

- SupraMotion employs superconductors to create magnetic levitation, enabling contamination-free, contactless transport even through barriers.

- Festo has successfully demonstrated automated vertical transport and filling of lab containers using SupraMotion in cleanroom environments.

- Festo is now inviting pilot project collaborations to advance this clean, automated handling technology.

Festo Research has developed SupraMotion superconducting technology as a future concept for automated contactless handling of objects from non-sterile to the clean areas of med labs and pharma facilities. SupraMotion also automates contactless weighing and test tube handling within clean environments.

Superconductors Anchor Contactless Processes

Superconductors are materials with unique magnetic features that lend themselves to contactless handling for dust and abrasion-free operation. The superconductor used in SupraMotion applications anchors the magnetic field of a permanent magnet, creating a strong but invisible bond that keeps the magnet and superconductor at a fixed distance from each other – even through walls, liquids, and vacuum.

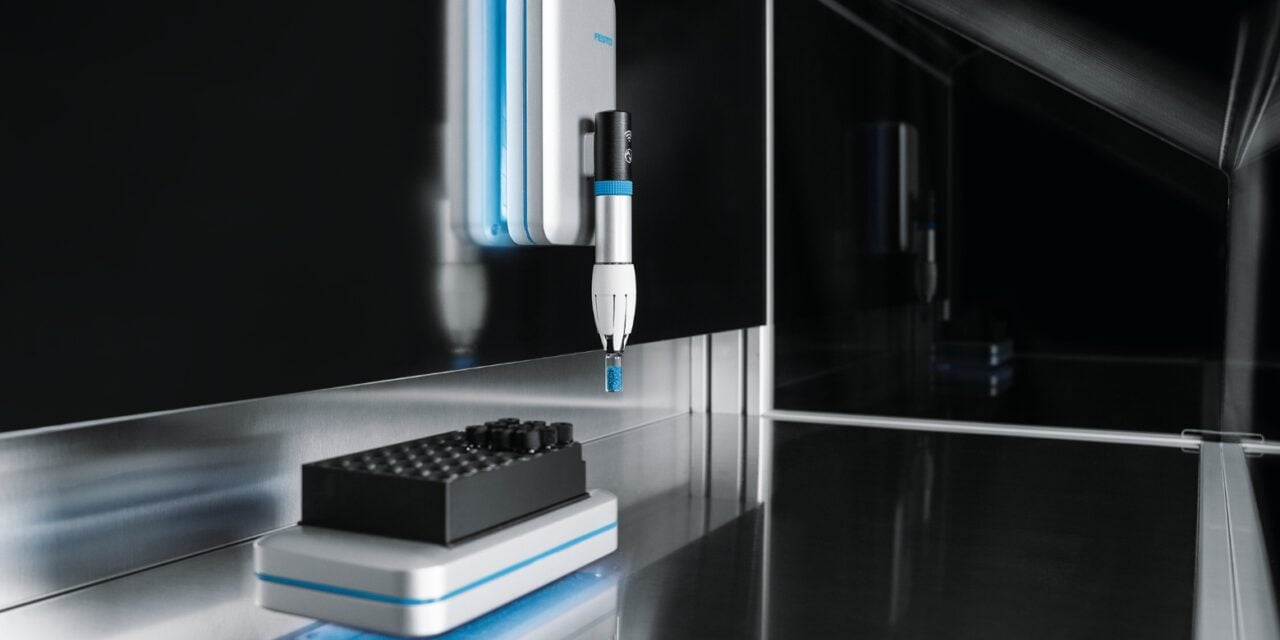

Levitation gaps of 10 mm and more are possible, allowing the SupraMotion superconductor to be on the non-sterile side of a barrier and the carrier plate on the sterile side where the plate moves samples and objects through automated processes such as capping/decapping, pipetting, and weighing.

SupraMotion Successfully Demonstrated

Recently, Festo demonstrated the automated contactless transport of covered microplates from non-sterile holding cells to a clean filling cell. Rather than using horizontal transport, the microplates were moved vertically up a wall and into the clean cell via a SupraMotion carrier. Vertical handling resulted in an ultracompact solution. The filling operation was 100% automated using Festo filling technology and associated solutions, including grippers.

Earlier this year, Festo demonstrated fully automated contactless filling and weighing of freeze-dry containers in cleanrooms. The SupraMotion modules and products from the Festo automation portfolio for contactless handling maintained the highest standards of cleanliness.

Festo is seeking pilot projects as the next development stage for this new solution that lowers the risk of contamination in clean environments. Those interested in pursuing pilot projects should write to [email protected].

Featured Image: A SupraMotion carrier offers contactless transport of test tubes. Image: Festo