The vendor-neutral platform is designed to connect instruments, robotics, and enterprise systems to improve throughput and compliance.

E Tech Group will introduce its Laboratory Automation and Industrial Robotics (LAIR) workflow orchestration platform at the ISPE Boston Area Chapter Product Show on Oct 1, at Gillette Stadium in Foxborough, MA.

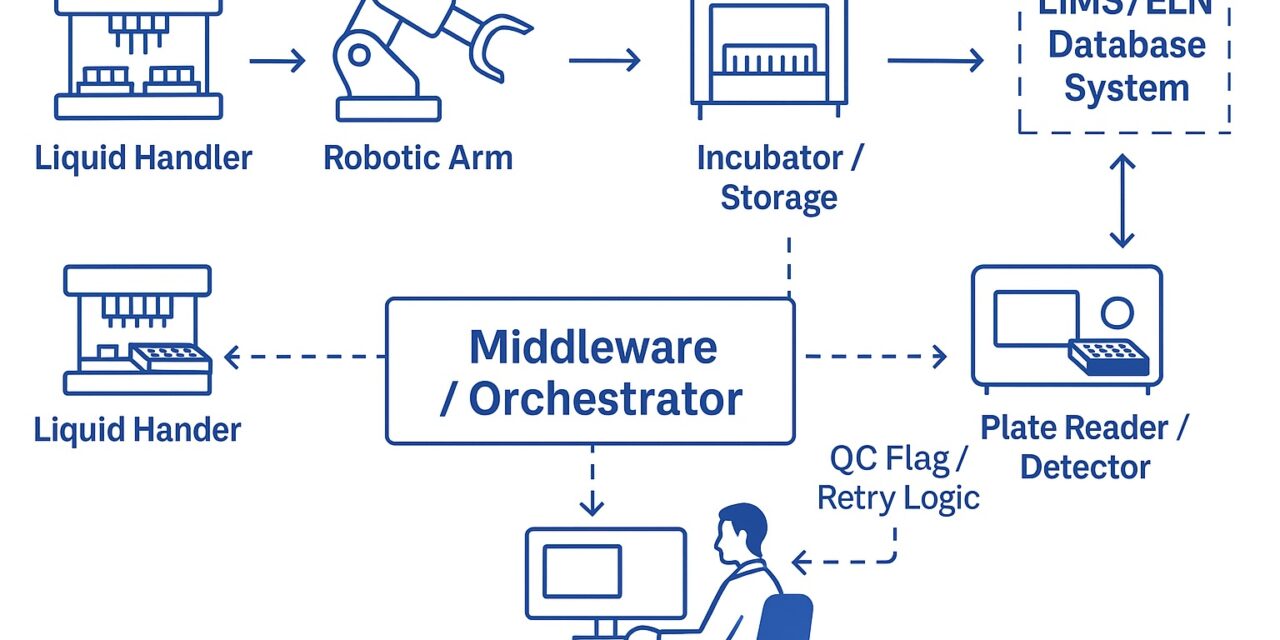

The vendor-neutral platform connects lab instruments, robotics, and enterprise systems into end-to-end workflows designed to increase throughput, strengthen data integrity, and ensure cGMP audit readiness for pharmaceutical, biotech, and diagnostics manufacturers.

LAIR orchestrates instruments, robotics, and enterprise platforms including LIMS, ELN, MES, and SCADA into scalable, compliant workflows. The system can reduce workflow turnaround times by up to 40% while ensuring secure, audit-ready data flows that align with IT/OT standards, according to the company.

Automated Protocol Translation and Execution

The platform translates scientific protocols into automated workflows, programming liquid handlers and robotic platforms to execute complex assays with precision and repeatability. This approach eliminates manual recording, reduces protocol variability, and minimizes operator error while maintaining compliance requirements.

In one implementation, LAIR automated tip replenishment across Hamilton liquid handling systems with a robotic refilling solution, eliminating mid-run interruptions and reducing labor requirements while ensuring full traceability and compliance.

The system extends beyond liquid handling through partnerships with Universal Robots, Brooks Automation, and Clayton Controls, bringing industrial robotic arms into regulated lab environments for sample transport, plate movement, and precision handling tasks.

Enterprise Integration and Compliance

LAIR integrates with enterprise data platforms to ensure compliance, scalability, and connectivity across the lab-to-factory continuum. The orchestration layer works with partners such as Retisoft for advanced workcell scheduling, enabling coordination and higher throughput.

At the plant-floor level, LAIR connects with Ignition by Inductive Automation and Rockwell controls, providing interoperability between laboratory systems and manufacturing execution environments.

The platform supports assay miniaturization and high-throughput screening, enabling labs to scale discovery while reducing reagent costs and variability. It is designed to integrate with Hamilton, Beckman, Tecan, and other leading liquid handling platforms.

Expanded Life Sciences Capabilities

The LAIR introduction builds on E Tech Group’s expanded life sciences capabilities following its acquisition of JSat Automation, which added expertise in Good Manufacturing Practice compliance services and Manufacturing Execution Systems. The combined capabilities provide integrated support spanning lab automation and robotics, compliance consulting, and multi-site MES deployment.

“By coordinating entire workflows, embedding compliance into every step, and connecting lab systems with enterprise platforms, E Tech Group’s vendor-neutral LAIR solution directly addresses the challenges life science manufacturers face with manual data entry, compliance pressures, and throughput bottlenecks,” says Matt Wise, CEO of E Tech Group, in a release.

Photo caption: Example of a LAIR workflow diagram, illustrating the workflow integration between instruments, robotics, and LIMS.

Photo credit: E Tech Group