In response to the coronavirus pandemic, a covid-19 test swab task force in the Biodesign program of the University of California, Los Angeles (UCLA), has developed a new nasopharyngeal swab that can be produced quickly on a 3-D printer. UCLA Health now has a protocol approved by the institutional review board and has launched a validation study of the new swabs.

“Compared with everything else that goes into testing, nasopharyngeal swabs are a relatively simple component,” says Gabriel Oland, MD, a general surgery resident at the UCLA Geffen School of Medicine and a fellow in the UCLA biodesign program. “But testing can’t happen without them.”

In April, Oland researched manufacturing companies—many of which were not medical-grade manufacturers—and worked with them so they could develop and mass-produce swabs that are safe and may be effective for clinical use. Because FDA, which normally requires lengthy and thorough testing and validation of new medical products, has been inundated, hospitals and manufacturers have been taking on the additional responsibility of validating such products themselves so that they can then retroactively provide supportive data to FDA.

“Many entities have completely pivoted in what they’re doing. Some print consumer goods; others print jewelry and athletic wear,” Oland says. “It’s difficult for these companies to make the transition to making medical-grade equipment, yet most of them are also manufacturing more or less at cost, with no intention of trying to gain economically from their contributions.”

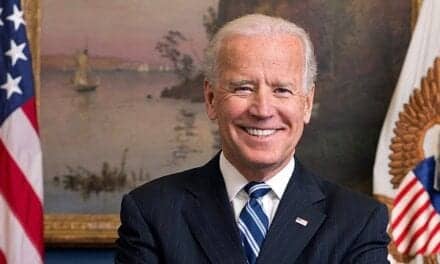

Not all swabs are alike, and not all can be mass-produced on 3-D printers. To meet the rapidly growing need for testing, the UCLA biodesign team found, the quickest-to-produce swabs consist of a single plastic material from tip to tip, with a lattice or a honey dipper design to collect a sample at one end.

“Given that it’s only using one material, 3-D printing is perfect for rapid output,” Oland says. “Once FDA gives its approval to the best-performing swabs, health systems won’t need to do as much clinical validation in-house. We’ll be able to start using the tests right away, potentially up to a few thousand a day at UCLA alone. I anticipate that very soon, extremely high throughput testing will be available nationwide. We are facing tough times, but we also have many reasons to be optimistic—the challenges we’re dealing with pose a unique opportunity for growth, and everyone with whom I’ve been working has risen to the occasion.”

Read more from UCLA Health.

Featured image: To meet the rapidly growing need for testing, the quickest-to-produce swabs consists of a single plastic material from tip to tip, with a lattice or a honey dipper design to collect a sample at one end. Photo courtesy Gabriel Oland, MD.