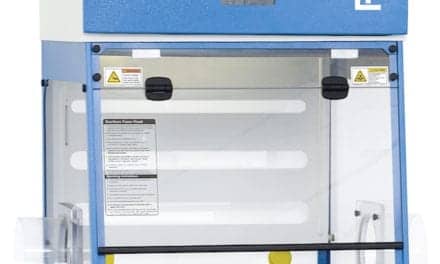

Flow Sciences has introduced its LEV III local exhaust ventilation hood, designed to provide personnel protection from chemical vapors generated during processes such as flash chromatography, rotary evaporation, and other process equipment applications. With the LEV III, applications and equipment can be moved out of fume hoods to conserve energy and increase valuable lab space.

Using a similar design for powder containment enclosures, the LEV III series was developed for vapors to be removed from the application and lab. Vapors are pulled to the rear of the enclosure, then up through plenums to keep laminar flow across the work surface and remove vapors effectively. Available with either laminated glass or acrylic panels, the LEV III can handle many applications and chemical uses.

For ease of loading and unloading equipment, the LEV III features a front sash that makes it simple to load equipment, then run the application either with an open face or with a very small face opening to save energy. The chemically resistant phenolic base is dished to maintain spills and coated to protect the work surface from harmful chemicals. The enclosure is lightweight, making it easy to move as the dynamics of the laboratory space changes. The LEV III comes standard in 2-, 3-, and 4-ft options, and custom options are also available.

For more information, visit Flow Sciences.

Featured image: The LEV III local exhaust ventilation hood by Flow Sciences.