Nanopec, Tucson, Ariz, has introduced MetaFluorex, a new class of ceramic films designed to enhance in vitro diagnostic (IVD) test kits, significantly reducing costs, upgrading test performance, and improving patient outcomes.

Many IVDs use fluorescent light from reporter molecules (tagged antibodies) to indicate the existence of an antigen in a patient’s sample, such as pathogens (bacteria, fungi, proteins, viruses), gene mutations, or a tumor biomarker. In early stages the amount of fluorescent light produced by the reporter molecule may be insufficient to yield a definitive positive test, yielding instead a so-called false negative.

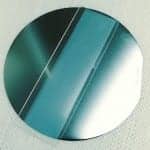

Figure 1. Suitable for in vitro diagnostic applications, a 10 cm x 10 cm wafer of MetaFluorex ceramic film from Nanopec, Tucson, Ariz.

Nanopec’s ceramic films are intended to address several such challenges relating to incumbent IVD technologies. A false-positive reading, telling a healthy patient that he is sick, for example, has an emotional impact but is not life-threatening. Retesting is a simple corrective action that can prevent some individuals from undergoing unnecessary, costly, or harmful treatments. Conversely, a false-negative reading, telling a sick patient he is healthy, can have serious, and potentially even fatal, consequences.

In initial testing, MetaFluorex enhanced fluorescent signals by factors as large as 100 times, depending on the assay, when compared to the glass slides currently used for IVDs. Such high enhancement decreases the likelihood that a patient will receive an incorrect diagnosis because the fluorescent signal is too weak or the biomarker concentration is too low to be detected. The ceramic films are made without cytotoxic materials and are safe to use in the presence of living cells.

Incumbent IVD tests also use costly reagents, such as primary and secondary antibodies. Instruments with high sensitivity are often needed to compensate for low signals. Because MetaFluorex ceramic films produce enhanced fluorescent signals, labs can achieve a significant reduction in the use of such costly consumables.

Cancer and debilitating chronic conditions can greatly benefit from early diagnosis and intervention. Due to its nanostructure and atomic composition, MetaFluorex fluorescence enhancement can lead to earlier detection by reporting lower biomarker concentrations. MetaFluorex requires fewer antibodies and biomarkers to achieve signal-to-noise ratios superior to comparable diagnostics on modified substrates (nitrocellulose or frosted, patterned, or dielectrically modified glass slides).

“We believe that there is an unmet need in the healthcare industry for cost-effective materials and processes that can increase the sensitivity of in vitro diagnostics while requiring lower amounts of costly consumables,” says Mario Blanco, PhD, CEO of Nanopec. “Our technology has the potential to save lives and lower healthcare costs by boosting bioassay signals to significantly reduce false negatives from in vitro diagnostics. We feel that we are heralding a new ‘gold standard’ that represents an important opportunity for the healthcare industry to increase IVD’s price performance and improve patient outcomes through earlier detection.”

Nanopec’s patent-pending process allows high-volume production at lower cost entry points than glass substrates. The atomic structure of MetaFluorex also eliminates autofluorescence in biological samples, a common problem that confounds some fluorescent signals.

For more information, visit Nanopec.

Featured image: Discs of MetaFluorex ceramic film from Nanopec, Tucson, Ariz. MetaFluorex is available in an array of formats and dimensions to suit customer needs.