This post is a sidebar to our April 2014 feature on Safety Products.

In 2013, OSHA’s number-two violation involved harard communications issues, most of which dealt with the United Nations’ GHS (Globally Harmonized System of Classification and Labeling of Chemicals) noncompliance. It is essential for companies to be knowledgeable about these regulations, not only to avoid OSHA violations, but to ensure the safety of their workers and clients who handle their products.

Teklynx, based in Whitefish Bay, Wis, which offers barcode-labeling software, has solutions specifically tailored to ensure that companies are in compliance with GHS. With so many lab safety issues remaining a major concern for many organizations, vendors offer such solutions as biohazardous waste disposal, disinfectants, spill containment, eyewash and shower, eyewear and face protection, gloves, and lab coats. But what about software?

Teklynx approaches the problem from the standpoint of ensuring that lab samples are correctly labeled. Teklynx, with more than 600,000 application installations globally, provides barcode and label software that offers label design, label printing, label management, and data collection solutions to small, medium, and enterprise labs.

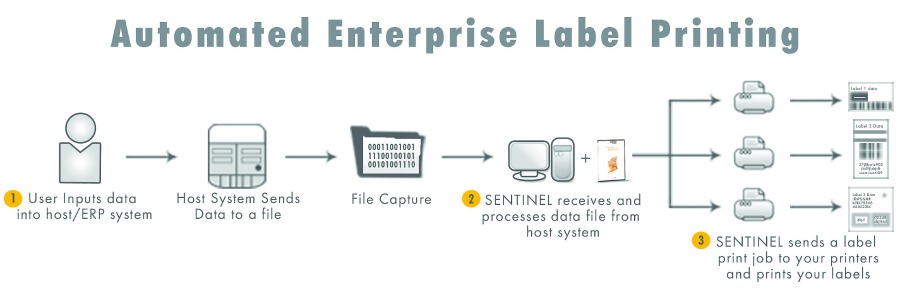

CODESOFT plus TEKLYNX’s SENTINEL software enables users to integrate printing into the labeling process.

“We offer a wide variety of enterprise label management solutions, but the core of our business has always been our barcode label design software,” says Nick Recht, the company’s enterprise product manager. He says the software’s most robust features address compliance requirements and integrate with clients’ databases to allow for variable data within label designs. “Codesoft plus Teklynx Sentinel software enables users to integrate printing into the labeling process. Sentinel allows for seamless print automation from Codesoft and prints the labels; the fully automated process from design to print speaks to safety compliance by eliminating manual entry, thus reducing errors,” he says.

Labels for clinical labs may differ from other labs because they need to fit a lot of information into a small label that can fit onto a test vial or wristband—about five lines of data on a 1 x 1-inch space. “With Teklynx barcode software, as long as the data exists, the labels at the lab can be formatted to fit differing needs while conforming to Health Level Seven (HL7) standards,” Recht says.

The company’s Label Archive solution offers additional security in the design of the label template. “Label designs in the lab aren’t that complex, but the processes associated with gathering the data and printing the labels can be. One feature of the software keeps a full history of each template, and if a prior error such as bad data or a bad request has occurred, the archive system enables easy analysis and prevention, ensuring that the errors don’t happen again,” he says.

Recht adds that Teklynx Central CFR and Teklynx Central GHS offer targeted solutions to support industry-specific standards. For example, Teklynx can support GHS compliance with chemical labeling requirements by creating labels that accurately identify chemicals and offer maximum traceability. The software is accessed via a browser-based printing interface and offers out-of-the-box automation and security.

Recht notes, “As a labeling software vendor, Teklynx is committed to offering options to benefit organizations that need to comply with regulations or compliance standards such as GHS, CFR, UDI. We make it a priority to help organizations mitigate safety risks.”