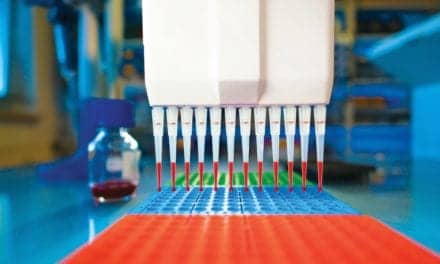

The 3D Bloom system from CellSpring will be automated on the Freedom EVO workstation by Tecan Group.

Tecan Group Ltd, Männedorf, Switzerland, and CellSpring, Zürich, Switzerland, a biotech spin-out from ETH Zurich, have announced a comarketing agreement to automate the latter’s 3D Bloom system on Tecan’s Freedom EVO workstation.

Through the collaboration, Tecan seeks to expand its automated 3D cell culture portfolio, allowing scientists to take advantage of a high-throughput technology with an extended cell viability period of at least 7 days in the assay matrix.

The adaptive 3D Bloom biopolymer platform is compatible with all cell types and is ideal for both mono- and coculture assays. 3D microtissues can be prepared in microplate format within minutes, and analysis is carried out while still in the culture matrix.

Four worktable capacities comprise Tecan’s Freedom EVO series, which was developed to offer precision, reliable liquid handling, and easy-to-use robotics. Whether 75 cm, 100 cm, 150 cm, or 200 cm, each unit supports modular configuration, and can be combined with a variety of robotic arms, liquid handling tools, and application options.

“As a leader in the field of automated 3D cell culture, Tecan is delighted to be working with CellSpring to implement its microplate-based 3D Bloom platform on the Freedom EVO,” says Kevin Moore, manager of liquid handling products and application management at Tecan. “This will allow scientists to benefit from straightforward, high-throughput automation of a 3D cell culture process offering long-term cell viability.”

“CellSpring is excited to partner with Tecan to bring automated, simple, 3D cell culture solutions to customers,” adds Chris Millan, PhD, chief technology officer at CellSpring. “The benefits of our 3D Bloom platform—versatility and reliability—are now available at scale using the Freedom EVO.”

For more information, visit Tecan or CellSpring.