Freeing up staffing utilization

The core lab performs more than three million chemistry tests annually on the Siemens ADVIA LabCell, which processes more than 2,000 tubes per day.

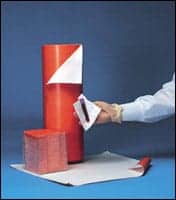

When running a clinical laboratory, there are several goals that most share: increase throughput, improve productivity, and reduce errors. At the Jacobi Medical Center, New York, the lab was able to achieve these goals through the implementation of Siemens’ ADVIA® LabCell® automated system, adding to its existing semiautomated system. The ADVIA LabCell system helped the lab reduce costs—fewer techs were needed, a major benefit with the current personnel shortage—and decrease turnaround time. Clinical Lab Products recently spoke with Joseph Furgiuele, director of clinical chemistry for Jacobi Medical Center, to discuss the status of the lab before and after the use of the ADVIA LabCell, and where the lab stands in terms of future growth and progress.

CLP: What’s the history of the lab?

Furgiuele: The core lab is located in the Bronx, New York, at Jacobi Medical Center, a 457-certified bed, Level I trauma center. It services two offsite clinics and another hospital, which has 260 beds and is 6 miles away. The core lab performs over three million chemistry tests each year on the Siemens ADVIA LabCell, which processes over 2,000 tubes per day. What is unique is that the ADVIA LabCell allows us to have five different disciplines attached to the track—chemistry, immunochemistry, hematology, coagulation, and urinalysis—plus a centrifuge and a decapper.

Prior to using the ADVIA LabCell, we performed our chemistries on Siemens’ ADVIA WorkCell®, and before that, the lab consisted of nine workstations manned with 11 techs. Faced with an aging staff and a nationwide personnel shortage, my decision to get an ADVIA WorkCell and transition to Total Lab Automation (TLA) was done proactively. After 6 successful years using the system and saving nine techs, we decided to add hematology, where we were able to save additional personnel. Now, with the ADVIA LabCell, we perform preanalytical, analytical, and postanalytical procedures.

CLP: What is your personal history with the lab?

Furgiuele: I’ve been with Jacobi Medical Center for 48 years, and a member of pathology’s faculty at the Albert Einstein College of Medicine, Bronx, NY, for 25 years. I am the type of director that likes spending time in the lab and remaining hands-on. It is said that I’m very passionate when it comes to my work. For example, before turning over a new instrument to staff, I run it and report out the work. This way, I really know how well the instrument performs. Being at Jacobi for all those years, I’ve gotten to know the hospital staff and what they expect from the lab. By starting my day at 6 am, I get to see and work with every member of my team. I find automation, troubleshooting problems, and dealing with lab tests and instruments both challenging and highly rewarding.

CLP: Why did the lab decide to implement the automated ADVIA LabCell System?

Furgiuele: The decision to implement the ADVIA LabCell was done with the understanding that we can do better in the way that lab tests were reported out. I knew of the benefits of automation—the staff savings, decreased turnaround times, the improved patient safety—based on my experience with the ADVIA WorkCell. However, these savings were only seen in chemistry. It was now time to extend the benefits to hematology and to form a chematology system. This gave us lots of flexibility in staffing utilization.

CLP: Were there any difficulties installing the system? Did you experience any downtime?

Furgiuele: There were some minor difficulties that we encountered; you have to know that we brought in three new systems: new instruments, the track, and Siemens’ CentraLink™ Data Management System. The first thing we did was install the new instruments and get them online. After a few months, we connected the CentraLink system to the instruments; by the time the area was ready for the track, we were completely proficient with the instruments and CentraLink. Next, we connected the instruments to the track. This whole process took 6 months. By setting the system up in steps, it alleviated any downtime.

CLP: How has the new system improved throughput?

Furgiuele: Having TLA allows us to do work much faster. Since all of the steps are automated, our throughput has improved and our turnaround times have decreased so that we completely eliminated our stat lab. Also, now when a physician orders an add-on, the system automatically retrieves the sample and reruns the needed test. Before TLA, add-ons were a challenge.

CLP: How does the new system improve patient safety?

Furgiuele: We only require one chemistry tube to do all of our chemistries and immunochemistry tests. The primary tube is a low-draw 16x100 tube, which helps in preventing hemolysis and the need to reorder. Since the ADVIA® 1800 Chemistry System and ADVIA Centaur® systems require very little sample, we are able to minimize the need for multiple tubes. We do not need to make a pour-over tube, which eliminates the possibly of mislabeling. Drawing only one tube reduces the amount of blood taken from the patient.

CLP: What is the flow of data like in the new automated system? How is this superior to your previous model?

Furgiuele: A blood sample that comes into the lab is placed on the track via the sample manager or the SIQ gate. All samples that need to be centrifuged will be sent to the centrifuge, while CBCs and urines that don’t need centrifugation go directly to the analyzers. After the blood leaves the centrifuge, it automatically goes to the decapper before eventually proceeding to the proper instrument. When sampling is completed, the tube is either sent to the unload tray and archived, or if it needs to go to another part of the lab, it’s placed in a sort tray. At this time, if an add-on comes in, the tube is automatically retrieved from the unload tray and placed back on the track. One of the biggest advantages of automation is that you do not need people to move the tubes to the different stations—once the tube hits the track, all the tech has to do is verify the results through the CentraLink system, assuming the results haven’t already been autoverified. The ADVIA LabCell is superior from our semiautomated lab, where each step consisted of someone moving the samples along. Remember, automated systems don’t call in sick, and they don’t take breaks. The only area that may pose a problem is loading the samples onto the track.

CLP: Do you have any sort of outside benchmark or indicator that measures lab efficiency before and after implementation?

Furgiuele: Before we implemented the ADVIA LabCell we counted the number of stats that came into our lab daily. We were concerned that implementation of a new automation system would slow things up, and the number of stats would increase. We hoped the number of stats would stay the same or only slightly increase, but, to our amazement, the number decreased. We followed up on this observation with a turnaround study and noticed that our turnaround times decreased by 5 to 8 minutes. Also, we were now able to provide around-the-clock testing. A test that was only done during the daytime, or perhaps once or twice a week, is now offered 24/7. Any test that is performed on the ADVIA LabCell is available to the provider at any time, making for better patient care and fewer misplaced samples.

CLP: What would you say is the lab’s biggest challenge right now?

Furgiuele: Create a system that will revolutionize the way our laboratory functions. Seeing unprecedented improvements in productivity, capacity, personnel optimization, and process. The drive is to boost efficiency while improving quality, increasing the throughput, and reducing errors. Therefore, our laboratory is committed to providing clinicians with the vital information they need for the accurate diagnosis, treatment, and monitoring of care to our patients.

CLP: What does the future hold for your lab?

Furgiuele: The future looks very bright. Clinical pathology plans to expand the LabCell platform by replacing an aging analyzer with Siemens Dimension Vista® 1500 Intelligent Lab System to our line, which will automate our pediatric section of the core lab and remove a separate workstation with additional personnel savings. As new tests become available, such as assays for vitamin D and syphilis, we will be adding them to our present menu without any additional techs needed. What I see in the future is one Total Laboratory Automation Line will allow tests to be processed with greater productivity and have superior efficiency. I honestly believe that in the future, Total Laboratory Automation is the only way clinical laboratories are going to survive in today’s health care marketplace.

Chris Gaerig is CLP’s associate editor.