The joint feasibility study demonstrates a closed-loop recycling solution for polystyrene Petri dishes and other healthcare plastics.

BD and Envetec Sustainable Technologies have completed a joint feasibility study demonstrating the ability to recycle polystyrene Petri dishes into high-quality manufacturing feedstock, opening potential pathways for sustainable recycling of laboratory plastics across healthcare supply chains.

The pilot study results suggest that similar high-quality polymers, including polystyrene, polyester (PET), polypropylene, and polyethylene, could be reused in the manufacturing supply chain after being safely disinfected and processed. These polymers are extensively used in medical devices and laboratory consumables.

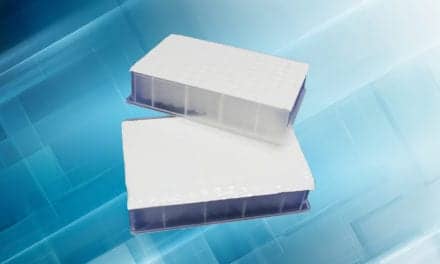

Envetec’s Generations technology converts regulated waste into recyclable polymer flakes through a validated, low-energy chemical disinfection process. In the BD pilot, unused BD BBL prepared plated media were processed as post-industrial material. The plates and their contents were shredded, separated, chemically disinfected, and converted into recycled, clean polymer flakes. These flakes were then extruded into polystyrene pellets and molded into new Petri dish prototypes.

“This pilot marks the first step in a broader effort to demonstrate the feasibility of recovering and recycling multiple types of plastic products across healthcare supply chains,” says Malcolm Bell, CEO of Envetec Sustainable Technologies, in a release. “By creating a proof of concept for a pathway that allows regulated plastics to be safely treated and returned to productive use, we are opening the door to sustainable solutions that can help the industry avoid landfill and keep valuable materials in circulation.”

Expanding Applications for Healthcare Consumables

The companies see opportunities to expand the pilot program, reduce reliance on virgin plastic, and keep high-value polymers in circulation. The approach could potentially be applied to other high-volume healthcare consumables including blood collection tubes, syringes, medical tubing, and packaging materials.

“Single-use devices made of high-quality plastics play a critical role in modern health care due to safety, ease of use and scalability, but we recognize the long-term impact that these materials can have on the environment,” says Nikos Pavlidis, worldwide president, Diagnostic Solutions at BD, in a release. “This pilot, conducted by BD’s Sustainable Medical Technologies Institute, represents an important step toward enabling circular economy solutions for other high-volume healthcare consumables.”

Material property testing and molding feasibility were successfully completed during the study, demonstrating the technical viability of the closed-loop recycling process, according to a release from BD.

The completion of this feasibility study provides a foundation for broader implementation of closed-loop recycling solutions in laboratory and healthcare settings, potentially addressing sustainability challenges while maintaining the safety and performance standards required for medical applications.

ID 3312641 © Julián Rovagnati | Dreamstime.com