Pure materials and innovative filter designs promise better outcomes in a variety of laboratory settings

By Maria De Capua, MT(ASCP)

The modern pipette and its components have undergone significant evolution and practical redesign since the origins of pipetting in the 18th century (See companion article “Modern Pipetting: Four Centuries in the Making“). Following the 1980s introduction of multichannel liquid-handling devices with positioning stage bases for holding microplates, pipette tips, and reservoirs, however, pipette design experienced a 30-year period of relative inactivity.

While pipette design may have been stagnant during recent decades, the challenges relating to pipetting in clinical laboratory settings have been anything but static. During this period, issues related to the speed of analysis and quality of test results have become increasingly important. Automated liquid-handling stations have been developed in order to deliver results at a faster pace than manual operations. But as such technologies have entered the market, concern has shifted to whether the instruments are properly calibrated to perform tests correctly and yield reliable diagnoses.

Avoiding cross-contamination while handling samples has also become a primary—and yet, unmet—concern. Clinical laboratory professionals have recognized the need to prevent the entry of aerosol contaminants into equipment and samples—a requirement that is particularly critical in high-stakes situations where it is necessary to work with infectious disease pathogens.

In a market where “65% of all laboratory infections are caused by aerosols,” the alarm over aerosol contamination commands a high level of attention. Filtered pipette tips work to reduce the risk of aerosol-related contamination by means of designs geared toward preventing the laboratory formation of aerosol contaminants, which can remain airborne for long periods of time. Such designs also protect pipette shafts from contamination, and thereby reduce the risk of cross-contamination. With the improvements resulting from such improved pipette designs, filtered pipette tips are often used in contamination-sensitive applications, such as molecular diagnostics.1

The Dangers of Contamination

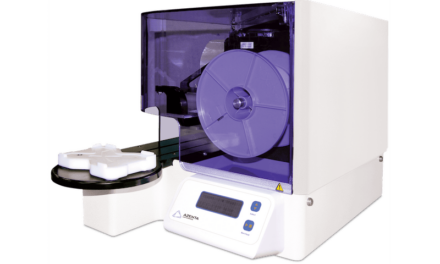

Aiming not only to meet needs for speed and reliability in sample retrieval and analysis, but to provide the higher level of cleanliness demanded by laboratory tests with greater sensitivity, Porex developed a new certified-pure pipette tip filter, the Porex Fortress (Figure 1). Initiated under the ‘Certified Pure Porex’ program, the pipette tip filter has been qualified among other porous polymeric materials via a stringent program of analytical, clinical, and life science testing procedures.2

Figure 2. In a clinical laboratory setting, the Porex Fortress pipette tip filter is designed to provide accurate results when performing diagnostic testing for hereditary diseases, infectious diseases, and more.

Recently introduced to the market, the new pipette tip filter represents the first advance that the liquid-handling realm has seen in years. By offering clinical laboratory professionals an advanced component that prevents cross-contamination and sample carryover without using additives, the Porex Fortress liquid barrier pipette tip filter has reawakened the dormant world of liquid-handling design.

Used to cleanly and carefully collect samples and reagents for applications ranging from analytical testing to molecular diagnostics, pipettes are heavily relied on by researchers and clinical laboratory professionals alike.

Sample retrieval is an extremely delicate and finicky task by nature, because the pipetter is working with substances that are subject to easy interference from the most minute outside elements or circumstances. Environmental factors like the temperature to which the pipette is exposed, user technique like the angle at which the pipette is held, and chemical issues like contaminants and aerosols, can all affect the pipetting process and its ability to yield accurate results (Figure 2).

The aerosols and liquids that find their way into an unprotected instrument can have multiple adverse effects. They can cause corrosion over time or damage the tightness of a seal within a pipette. They can also carry over to the next liquid transfer, altering the makeup of a sample and incorrectly influencing test results.

Figure 3. In a comparison between a standard pipette tip filter (left) and the Porex Fortress pipette tip filter (right), the standard filter effectively prevents aerosol contamination but can cause the sample to enter the pipette shaft, rendering the sample unusable due to difficult retrieval or possible contamination. The Porex Fortress technology, in contrast, blocks aerosols and allows for clean sample retrieval.

The danger of a contaminated sample is simple: if a source is unreliable, test results will be equally unreliable. Retaining sample quality is key, whether in a research laboratory, where testing and analysis are the bread and butter of the work; or in a clinical laboratory setting, where testing is done to provide health information and diagnoses to patients. Samples rendered unusable can disturb operations, causing delays, additional costs, and overall uncertainty.

They can also result in serious issues for patients, who are depending on a clinic to provide trustworthy, accurate information. Receiving an incorrect diagnosis not only wastes a patient’s time and money but can also be physically harmful to the patient when decisions about the start, end, or adjustment of a treatment follow an incorrect diagnosis.

In many cases, patient specimens are only available in finite amounts, making it imperative that test samples be reliably retrieved on the first attempt. If the makeup of a sample is altered by exposure to contaminants, or if the sample is improperly transported or tested, test results may need to be voided. A contaminated sample can also become locked inside the pipette tip itself, damaging any chance for preservation and potentially passing contamination along to the next test performed with the same pipette. Such possibilities pose serious complications for situations in which returning to the source for a new specimen either is not an option or would be too time-consuming.

While all test applications depend upon effective pipetting, molecular diagnostics that make use of target amplification via polymerase chain reaction (PCR) are arguably the procedures for which it is most critical to avoid contamination. Molecular diagnostics of this type have become common for such applications as diagnosis of infectious diseases, monitoring of hereditary diseases, and testing for genetic carriers in prenatal and preimplantation stages. For these types of tests, PCR is used to amplify the DNA within a sample and generate millions of copies of a sequence. If the original sample becomes tainted to any degree, all of the subsequent copies will also be inaccurate, potentially leading to an incorrect diagnosis. In situations where the test results are being used to detect the presence of pathogens or genetic conditions, false readings can cause immense damage.

Supporting Next-Gen Pipetting

Designed to eliminate concerns about impure samples and unreliable diagnoses, the Porex Fortress pipette tip filter can be used for a range of methodologies. The technology incorporates inert and hydrophobic filters (meaning they are naturally strong enough to stand against contaminants) that function as a barrier to seal out unwanted fluids and aerosols, keeping them from infiltrating the pipette shaft (Figure 3). Filters protect samples from aerosols that are preexisting in the pipetter from previous procedures, as well as from those that are created when the sample liquids are aspirated.

Figure 4. By optimizing the airflow in the pipette shaft, the Porex Fortress pipette tip filter allows for proper aspiration to occur and simultaneously blocks potential contaminants that can alter test results.

While this protection occurs, the filter also optimizes airflow to enhance the accuracy of the procedure. This optimized airflow allows for aspiration to occur—necessary for the sample to be captured by the pipette—while simultaneously thwarting the entrance of harmful particles (Figure 4). The result of such features is a sample that remains safe from interference and creates a reliable and confident test result.

Despite being robust enough to block unwelcome elements, the new filter is made with a proprietary polyethylene (PE) matrix material that is free from carboxymethyl cellulose (CMC) or cellulose gum, and other additives that can leach into samples (Figure 5). Use of such materials is not the case for all filtered pipettes on the market. The importance of additive-free manufacturing lies in the tendency for these elements to infect samples just as deeply as outside contaminants. One analyst evaluates the design and manufacture of pipette tips as follows:

Pipette tips appear to be technically simple, almost commoditized, yet their design and manufacture require significant thought and engineering. . . . Exquisite engineering notwithstanding, no pipetting system performs reliably if the tip discharges contaminants during operation. . . . Tips not manufactured under pristine conditions and thoroughly inspected may harbor adventitious biological or chemical contaminants as well. For plastics, of which tips are made, leachables and extractables may affect data fidelity and experimental results in insidious ways.3

Table 1. Results of proton induced x-ray emission (PIXE) testing of the porous polymers of various Porex pipette tip filters, showing low levels of elemental contamination compared to competitive samples. The Porex Fortress has also been qualified under the ‘Certified Pure Porex’ program, which incorporates stringent analytical, clinical, and life science testing procedures.

The creation of a liquid-barrier filtered pipette without employing additives represents an industry first and sets a new standard for liquid handling. Through tests using pyrolysis gas chromatography mass spectroscopy (PYMS), proton-induced x-ray emission (PIXE), and liquid chromatography mass spectroscopy (LC-MS), the pipette tip filter received a Certified Pure Porex designation. The materials were found to have virtually no material additives, contaminants, or heavy metals that cause interferences in clinical and laboratory testing (Table 1). They have 99.9% bacterial aerosol filtration efficiency (BFE) and were also verified to be noncytotoxic and nonhemolytic via additional testing from independent labs.

According to market examination by Porex, this testing is the most extensive qualification program for porous polymeric materials. It fills a critical gap, the company says, in the progression of developing standardized methodologies for the analysis of leachables and extractables in plastic consumables.2

The brainchild of researchers anticipating the needs of the next pipetting generation, the new filter was designed to remove impurities that could jeopardize test results in future classes of instrumentation and ultimately provide the highest level of purity available in a pipette. The novel technology went beyond the standard concerns of leaching and extractables encountered within aspiration itself, and took the full range of possible contaminants into consideration—both external and internal. By focusing on the material foundation of the pipette, researchers approached sample purity from the very start of the pipetting process, recognizing that preventing contamination during aspiration was an irrelevant standard if the sample was being introduced into a pipette that harbored unknown contaminants from the start.

Figure 5. Free of carboxymethyl cellulose (CMC) and other additives, the Porex Fortress is constructed with a proprietary polyethylene (PE) matrix material and proven through testing to contain no contaminants or heavy metals that can interfere with samples.

The researchers therefore aimed to prevent cross-contamination at all stages, a challenging and critical objective in preserving sample quality. They also worked to address the difficulty of conducting analysis on reduced sample sizes, which provide little to no room for error or do-overs.

Once the filter’s base technology was refined and able to meet these needs, the next feat was to create a product that—as filters gained popularity—could be easily standardized for use in clinical laboratories all over the world (Figure 6). Factors like sophisticated manufacturing techniques and eco-friendly products are reportedly responsible for driving the growth of the filtered pipette.1

The value of a filtered pipette made with certified-pure materials is recognized by independent organizations that compare liquid-handling materials available on the market. Laboratory managers or purchasers with the goal of true testing assurance “should look for filters made of pure polyethylene, without sealing additives, and rely on [their] vision to ensure that liquid is not aspirated into the pipette. This will ensure sample integrity.”4

Conclusion

The benefits of filtered pipette tips, including especially the ability of filtered pipette tips to reduce aerosol contamination, have gained widespread recognition.1 Still, filtered pipette tips have not yet landed in every clinical laboratory.

Such slow market penetration for a highly regarded product may be the result of inadequate marketing to the customers that would most benefit from the product. But it may also be that the lower costs of filtered pipette tips have not yet been fully passed along to customers, allowing to stand the traditional price difference between filtered and nonfiltered pipette tips. To reduce the costs of their test methodologies and improve their bottom lines, laboratories often rely on a combined inventory that includes both filtered and nonfiltered pipettes. Nonfiltered pipettes are typically used for tests that are considered less temperamental or delicate, while the more-expensive filtered pipettes are often saved for tests that are considered more sensitive.

Figure 6. Applicable to both manual and robotic liquid-handling methods, the Porex Fortress pipette tip filter aims to standardize pipette inventory within laboratories.

Today, testing assurance comes at very minimal cost. The price difference between filtered and nonfiltered pipettes is almost negligible, leaving laboratory managers with little reason to purchase the nonfiltered option.

Eliminating the varied inventory in a lab and supplying only filtered pipettes can also contribute to more simplified operations. With just one instrument in a facility, no decisionmaking has to occur over whether a specific test is ‘worth’ the use of a filtered pipette. Using only filtered pipettes means a laboratory can elevate its integrity and demonstrate commitment to quality test results across the board, resulting in better outcomes for patients, research projects, and overall costs.

Now that new life has finally been breathed into the liquid-handling market, researchers will continue to make new advances, and new designs will likely take shape in the years to come. Innovations will focus on quicker turnaround times to meet the needs of today’s fast-paced patients, allowing for earlier delivery of accurate and reliable diagnoses and, therefore, earlier initiation of appropriate therapies. More personalized approaches to medicine may also emerge with liquid-handling systems that are more intuitive, user-friendly, and mobile. Finally, with liquid-handling methodologies in demand for testing in a variety of settings, but with professional laboratory scientists in short supply, development of automated systems seems likely to continue—perhaps with some urgency.

When it comes to the pipette, the development of a certified-pure filtered instrument may be just the beginning. It could one day become the new norm for labs across the globe to stock only filtered pipette tips. Just as the once-common technique of mouth-pipetting now seems unsafe and unhygienic to the modern lab professional, it is possible that nonfiltered pipettes and filtered pipettes that are not certified-pure will be regarded in the same manner.

The result will represent a qualitative improvement in clinical outcomes and a higher standard of performance in the science and practice of liquid handling.

Maria De Capua, MT(ASCP), is a vice president at Porex Corp. For further information contact CLP chief editor Steve Halasey via [email protected].

Featured Image: The Porex Fortress technology uses inert and hydrophobic pipette tip filters to prevent fluids and aerosols from contaminating samples or pipettes, keeping samples protected and test results reliable.

References

- Filter Pipette Tip Market Research Report 2021. Pune, Maharashtra, India: QY Research, 2016. Available at: www.millioninsights.com/industry-reports/filter-pipette-tip-market. Accessed July 3, 2018.

- Harris KT, Mao G, Li G. Systematic Analysis of Leachables and Extractables in Clinical Polymeric Consumables. Fairburn, Ga: Porex, 2013. Available at: www.porex.com/files/documents/Porex-AACC-Poster-Session_July-2013.pdf. Accessed July 3, 2018.

- DePalma A. The latest in pipette tip design [online]. Lab Manager. December 15, 2016. Available at: http://www.labmanager.com/product-focus/2016/12/the-latest-in-pipette-tip-design#.WykI1RJKiu6. Accessed July 3, 2018.

- Anwari A. Pipette tips: the link to successful science [online]. Biocompare. August 28, 2013. Available at: www.biocompare.com/bench-tips/141356-pipette-tips-the-link-to-successful-science. Accessed July 3, 2018.